Career Opportunities

HOW TO APPLY

All applicants should send in a cover letter and CV (Resumé), to Emily Emond. Please enter the name of the job you are applying for in the subject line.

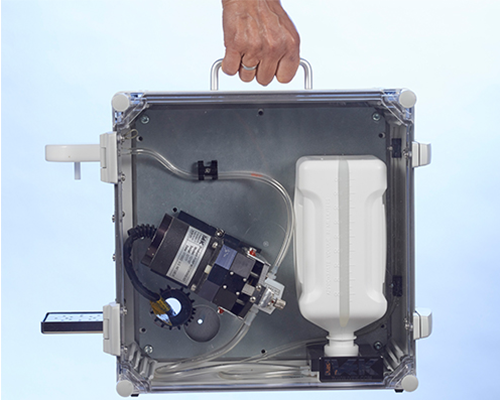

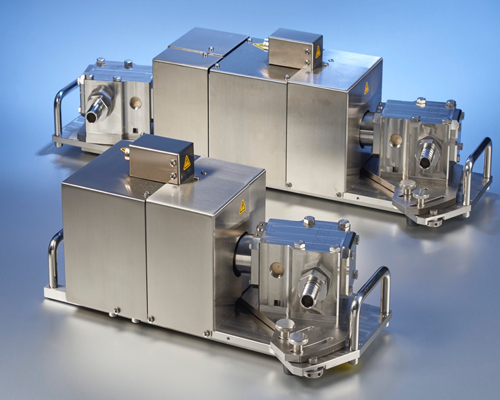

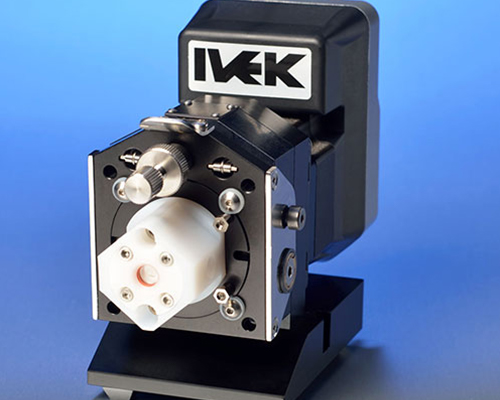

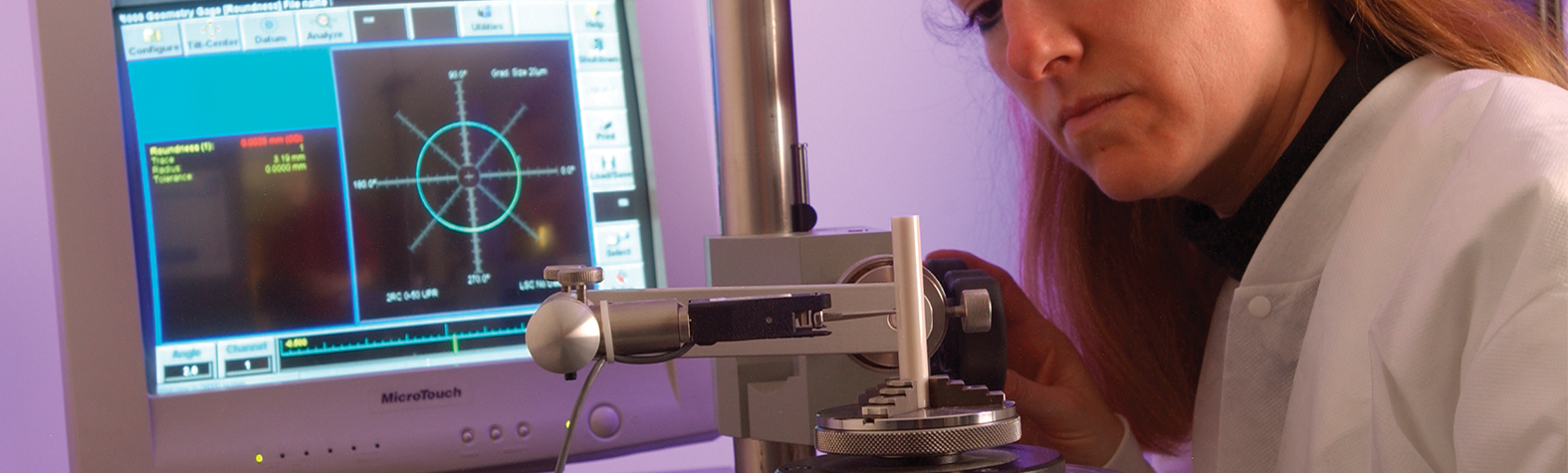

IVEK Corporation is a leading manufacturer of precision liquid dispensing and metering systems. We are committed to innovation, quality, and customer satisfaction, offering engineers an environment that fosters professional growth and technical excellence.

IVEK Corporation strives to provide a pleasant, safe and friendly workplace. IVEK employees are competent people who understand and meet our objectives, and who accept, with open minds, the ideas, suggestions and constructive criticism of fellow employees.

We believe in direct access to management. IVEK is a company where you can approach your supervisor, or any member of management, and discuss any problem or question. We are proud of the fact that many of our original employees have remained with the company during its growth.

The most important part of IVEK will always be its employees. IVEK Corporation is an equal opportunity employer offering competitive wages and excellent benefits.

CURRENT JOB OPENINGS

Associate Engineer - Mechanical (click to view)

Description:

The Associate Mechanical Engineer is an entry-level role for recent graduates or early-career professionals looking to launch their engineering career. This position supports product development and process improvement efforts while providing hands-on experience in precision engineering and manufacturing.

Essential Duties and Responsibilities:

- Assist in the design, testing, and validation of mechanical components and systems.

- Apply engineering fundamentals to support product development and continuous improvement projects.

- Create and maintain engineering drawings, test reports, and documentation.

- Collaborate with engineers, technicians, and production staff to solve problems and ensure product quality.

- Learn and utilize CAD software, testing tools, and modeling systems under supervision.

- Participate in project meetings and contribute to technical discussions.

- Ensure compliance with company Quality standards, policies, and procedures, e.g., ISO 9000/13485, maintaining a quality mindset to ensure IVEK products meet or exceed customer expectations.

- Ensures compliance with various Regulatory requirements, e.g., IEC/EN/UL 61010-1, RoHS, etc.

- Perform any other required department tasks that may be assigned on an as-needed basis.

Education and Experience:

- Bachelor of Science in Mechanical Engineering or related field.

- 0–2 years of engineering experience (internships/co-ops welcome).

- Familiarity with CAD tools (SolidWorks preferred).

- Basic knowledge of materials, manufacturing methods, and mechanical systems.

- Strong communication, teamwork, and problem-solving skills.

Knowledge, Skills and Abilities:

- Develops knowledge of IVEK’s products and processes.

- Learns and applies formal engineering tools (CAD, testing equipment, modeling software).

- Basic knowledge of ANSI/ASME Y14 and Geometric Dimensioning and Tolerancing (GD&T)

- Reads and interprets relevant publications, standards, and regulatory materials.

- Applies fundamental engineering principles under supervision.

- Works collaboratively with immediate team members.

- Participation in group discussions, seeking to understand and contribute.

- Engaging with peers and supervisors to achieve project objectives.

- Contributes as a task-level participant on project teams.

- Relies on direction and mentorship while developing professional independence.

- Demonstrates accountability for assigned work and deadlines.

- Begins learning the organizational structure and key stakeholders.

- Shares and explains personal work clearly with the team.

- Participates in technical discussions, asking questions and offering input.

- Learns to interact with customers or technical staff in a professional manner.

- Documents processes, concepts, and test results clearly and accurately

- Ability to work efficiently on multiple design assignments simultaneously.

- Willingness to learn more advanced engineering concepts and share knowledge with others.

- Ability to work autonomously or in small teams, defining and meeting long-term project goals with minimal direction.

Training Requirements:

- ISO Quality Training and Awareness

- General Safety including office, assembly, machine shop, and lab areas

- IVEK Quality System Awareness (Quality Management System and Manual)

- SDS and Hazard Communication

- Electrostatic Discharge Awareness, Electrical Assembly Techniques

- Familiarity with IVEK products and product applications

Interrelationships:

- The Associate Mechanical Engineer reports directly to the Director of Engineering.

- In addition, the Associate Mechanical Engineer will be expected to work with other departments and personnel to answer questions, resolve discrepancies, assist in interpretation and correct errors as they relate to engineering specifications.

- Other areas of the company as required.

Physical Demands:

- Able to sit and work at a computer for extended periods of time.

- Occasionally walking and standing.

- Occasional work at a lab bench requiring setup and operation of equipment.

- Occasional use of light hand tools such as crimpers and soldering irons to develop prototype designs and perform troubleshooting.

- Able to perform general office activities: copying, filing, delivering and using the telephone.

- Able to stoop, kneel, bend at the waist and reach daily.

- Able to lift and move up to 25 pounds occasionally.

- Some travel to trade shows or customer sites may be required.

Personal Protective Equipment:

- Safety Glasses in Machine Shop and Labs as required.

- Hearing protection as required.

- Chemical resistant apparel such as smocks and gloves when working with hazardous materials.

Work Environment:

- Work performed in an office environment.

- Work performed in manufacturing environment.

- Exposed to any number of elements but with none present to the extent of being disagreeable.

- May spend time in well-lit laboratory.

- General office environment. Work is generally sedentary in nature but may require standing and walking for up to 10% of the time. The working environment is generally favorable. Lighting and temperature are adequate, and there are no hazardous or unpleasant conditions caused by noise, dust, etc. Work is generally performed within an office.

Benefits:

- Medical, Dental & Vision Insurance- Minimal waiting period. Full-time employees are eligible for benefits on the 1st of the month following hire date.

- Health Savings Account- Includes employer contributions

- Life Insurance- Basic plan covered by employer with option to increase.

- 401K with company match

- Paid vacation, sick and personal time.

- 9 paid holidays

- Education Reimbursement

- Fitness room with showers on-site

Job Type: Regular

Job Status: Full Time

Pay Type: Annual Salary $55,000-$65,000 a Year

CNC Machinist (click to view)

Description

IVEK is a select manufacturer specializing in the design and manufacture of precision liquid metering and dispensing systems. IVEK Corporation is seeking an experienced CNC Machinist. Machining parts using CNC lathes and machining centers as well as manual machining equipment. Inspect and measure parts using standard inspection tools.

Essential Functions:

- Perform all CNC Machining tasks.

- Perform all Manual Machining tasks.

- Measure and gauge parts.

- Assembly as required.

- Perform maintenance on machines as required.

- Maintain the work area and equipment in a clean orderly condition and follow prescribed safety regulations.

- Complete any and all tasks assigned by supervisor.

Job Knowledge, Skills and Abilities:

- Must be flexible and able to handle wide variety of machining tasks.

- Ability to work independently and with others in a small group.

- Ability to read and work from prints incorporating geometric dimensioning and tolerances.

- Ability to inspect and measure machined parts.

- Mechanical Aptitude and willingness to learn and grow.

- Team player with positive demeanor.

Education and Experience

- High School diploma or GED required

- 2 years of experience or vocational training on manual milling machines, lathes, grinders, drills and other machinery

- CNC lathe an machining center experience a plus.

Benefits

- Medical, Dental & Vision Insurance- Minimal waiting period. Full-time employees are eligible for benefits on the 1st of the month following hire date.

- Health Savings Account- Includes employer contributions

- Life Insurance- Basic plan covered by employer with option to increase.

- 401K with company match

- Paid vacation, sick and personal time

- Education Reimbursement

- Fitness room with showers on-site

- Job Type: Regular

- Job Status: Full Time

- Travel: No Traveling

- Minimum Degree High School or Equivalent

- Pay Type: Hourly Wage $21.00-$27.00 an Hour

Mechanical Technician (click to view)

Description

IVEK is a select manufacturer specializing in the design and manufacture of precision liquid metering and dispensing systems. We are seeking an experienced Mechanical Technician. You will be part of a growing, fast-paced team. The primary objective of this position is to assemble IVEK products which meet our performance, quality, and customer delivery expectations. Job duties include all phases of standard and custom assembly, including motor bases and actuators.

Essential Duties and Responsibilities:

- Assemble standard mechanical and custom components.

- May be required to perform minor soldering.

- Identify faulty parts during the assembly process and test assembled parts or products to check quality and function ability.

- Keep the work stations orderly. Store and maintain tools, parts, test equipment and documentation, etc.

- Follow targets and deadlines for assembling process.

- Follow safety procedures, environmental guidelines and standard rules and regulations during the assembly process.

- Assist in R & D area when needed.

- Build all sub-assemblies and accessory kits.

- Operate laser machine.

- Work and read from prints, and follow procedures required to perform all aspects of mechanical assembly.

- Operate all test and measuring equipment needed to perform the above.

- Complete any and all tasks assigned by supervisor.

- Assist in the development and implementation of efficient work instructions and procedures.

- Train other employees, as required, in work instructions and procedures.

Education and Experience

- High School Diploma

- 1-2 years technical and/or mechanical assemblies experience a plus.

Knowledge, Skills and Abilities:

- Technical aptitude.

- Ability to read and interpret drawings, sketches and engineer instructions.

- Understand and follow assembly procedures.

- Capacity to perform repetitive tasks.

- Organized with ability to maintain various open orders.

- Requires good manual dexterity to work with small, detailed objects.

- Team player with positive demeanor.

Benefits

- Medical, Dental & Vision Insurance. Minimal waiting period. Full-time employees are eligible for benefits on the 1st of the month following hire date.

- Health Savings Account. Includes employer contributions

- Life Insurance. Basic plan covered by employer with option to increase.

- 401K with company match

- Paid vacation, sick and personal time

- 9 Paid holidays

- Education Reimbursement

- Fitness room with showers on-site

- Job Type: Regular

- Job Status: Full Time

- Pay Type: Hourly Wage $18.00-$20.00 an Hour