DIGISPENSE® STRIPER Reagent Dispensing System

Precision Reagent Dispensing Device for Lateral Flow Assays (LFA)

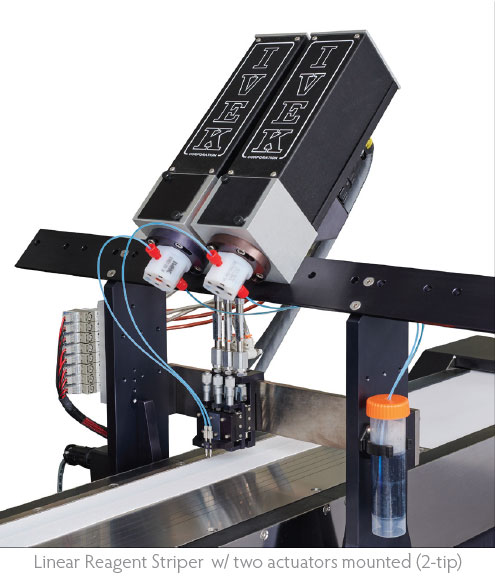

The IVEK Digispense® Reagent Striper, is a semi-automatic linear reagent dispenser positioning/dispensing system intended for continuous non-contact fluid dispensing onto various substrates such as nitrocellulose for manufacturing lateral flow assays (LFA). The precisely controlled motions of the vacuum plate slide carriage and IVEK dispensers together provide for extremely precise and consistent reagent line impregnation.

Touch screen operation allows for immediate precise control over all system functions

and has virtually eliminated the need for mechanical adjustments. The flexibility of the Digispense® reagent dispenser striper

makes it an ideal research and development tool, as well as a full production machine. This system was

created with the specific needs and requests of the diagnostic manufacturer to ensure a quality lateral

flow test is the end result.

Download PDF

Digispense® Striper Reagent Dispensing System Overview

Designed for applications where simultaneous delivery of identical volumes of fluid is desired. A high-resolution servo-controlled actuator can control 8, 10, or 12 ceramic pump modules at once.

All parameters are digitally selected via RS232 computer signal or touch screen interface.

Benefits and Features of the Digispense® Linear Reagent Dispensing Striper

With a combination of engineering, safety features, and advanced technology Ivek’s precision linear reagent dispenser can be used in laboratory and industrial settings with confidence and ease. IVEK’s careful balance of superior mechanical, electronic, and material engineering achieves linear reagent dispensing with high accuracy and repeatability critical to laboratory and industrial processes such as chemical analysis, synthesis, or biochemical assays.

- Up to 8 independently controlled continuous reagent lines and dispense tip positioning fixtures

- Substrate dimensions up to 110mm x 450mm accommodated (Max Strip Length 450mm)

- Continuous fluid impregnation operator selectable from 1-450mm long

- Custom vacuum plate holds membrane substrates firmly in place

- Linear travel rate operator selectable from 1-100 mm/sec

- Accuracy/Repeatability < 1% Cv

- Capable of pumping high viscosity fluids (1,000+ cps)

- Able to dispense materials with additives

- Optional bubble detection/loss of fluid sensor(s)

- Gantry mounted dispensers for maximum accessibility to pumping chambers

- Minimum spacing between dispense tips 5 mm

- Ultra high purity ceramic dispense tips with bore sizes from 0.003”-0.007” with 0.010” and 0.012” options as well.

- Designed for use with Digispense® 4000 controllers:

- Continuous dispensing rate operator selectable down through 0.1 μl/sec.

- Dispensers fitted with 1A – 4A pump heads, depending on flow volume required

- Digital volume and flow rate control adjustment

- LCD display of all dispensing parameters

- Automatic pump priming and reloading

- Micro-stepped pumps and bed for better resolution at low volume

- Computer interface – RS232 or EtherNet/IP™